Technical Team

C SAIL has 20 design engineers in the design department. Mr. Zhao is the department's chief engineer with over 20 years of experience in drying equipment research and development. He has in-depth knowledge on the requirements of drying equipment for various industries and knows a lot about customers' production process, thus always facilitating smooth communication with our clients. Led by Mr. Zhao, the engineering design team has solved various technical difficulties and obtained a significant number of national patents.

Technology Innovation- In the pharmaceutical and agricultural products processing industry, we have summarized the effects of temperature on different plants and the effect of drying time and drying temperature on farm products. By redesigning the single-layer structure to a multilayer one, upgrading the single-temperature drying to multiple-temperature drying, and utilizing low-humidity dry air, this difficulty in the drying industry can be solved.

- C SAIL obtained 3 technology innovations regarding energy savings, which enables the renovated drying equipment to minimize energy consumption by 25%. First, the heating power is reduced by redesigning the heater while the drying performance is not affected. Secondly, a unique heat exchange device is adopted to increase the heating efficiency. Finally, a thermal insulation structure is adopted to reduce heat loss.

- C SAIL optimizes UV drying equipment in two ways for energy savings. First, the inside of the drying equipment is equipped with lightbox isolation to reduce the radiation temperature of the UV lamp from 80°C to below 65 °C. Secondly, the standard voltage transformer is replaced by a stepless photo-electronic transformer to save energy by up to 25%.

Team Members

- Zhao Huawei (Chief Engineer)

- Mr. Zhao has been focusing on the research and design of drying equipment and non-standard automatic equipment since 2000. In 2005, Mr. Zhao founded C SAIL and worked as the chief engineer. Since then, working with other colleagues, Mr. Zhao has developed and manufactured a series of high-end drying equipment and automatic equipment, and has obtained a number of patents.

- Huang Chunqiu (Mechanical Engineer)

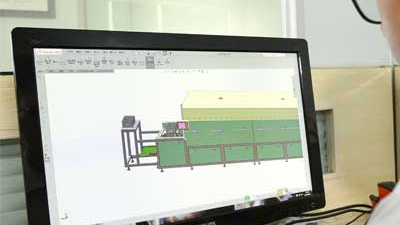

- Since 2008, Mr. Huang has been working as the mechanical engineer focusing on the research and design of drying equipment. With rich experience in automatic mechanical design and sheet metal design and manufacturing, Mr. Huang is skilled in Solidworks, PROE/CREO, UG 3D modeling, AutoCAD, etc. Mr. Huang has developed a range of non-standard equipment and improved a number of existing equipment. Besides, Mr. Huang has applied for many patents.

- Zhang Huawei (Mechanical Engineer)

- Since 2006, Mr. Zhang has been working as one of our mechanical engineers focusing on the research and development of drying equipment. With rich experience in the mechanical design of non-standard automatic CNC equipment and the research of mechanical properties, Mr. Huang has developed a series of non-standard equipment and drying equipment and improved many existing equipment. Mr. Huang has applied for many patents.

- Yang Meidan (Electrical Engineer)

- Since 2008, Mr. Yang has been working as the head electrical engineer focusing on the research and development of drying equipment and non-standard automation. Mr. Yang is very familiar with PLC, touching screen, single chip microcomputer, wincc, programming of vision processing system, R&D of digital circuit of I/O module, the international electrical safety standards like TUV, UL, CE, PES, SAA, as well as electrical drawing software, like AutoCAD, EPLAN.

- Li Zhi (Electrical Engineer)

- Since 2011, Mr. Li has been working as the electrical engineer focusing on the research and development of drying equipment and non-standard automation equipment. Mr. Li is very familiar with each type of frequency converter, servo, development of step motor driver, development of switching power supply, digital circuit and analog circuit, programming of PLC, touch screen, single chip microcomputer, wincc, vision processing system and international electrical safety standards like TUV, UL, CE, PES, SAA.